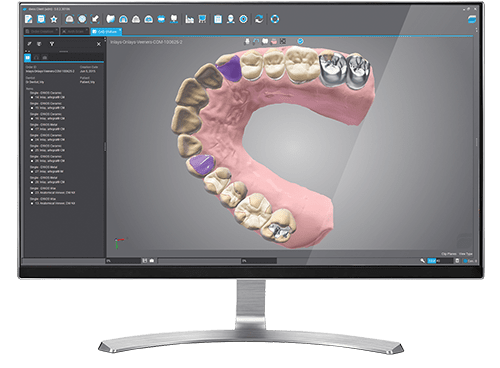

Closed-architecture systems will only work with select scanners, mills or printers.īefore choosing software, it is important to ensure compatibility with existing hardware and software, and that it comes with adequate training and support. Our specially trained technicians have mastered the. Open-architecture systems are capable of working with a range of hardware and software systems. CAD/CAM revolutionizes our business and becomes more integrated into every department on a daily basis.

The outer surface is milled to the desired shape and coping, removed from the die and sintered into the furnace for firing to full sintering.ĭental CAD/CAM software can be open or closed architecture. Alumina or Zirconia is dry pressed on the die and the temperature is raised to a temperature similar to the pre-sintering state. Additive technique by applying material on die.Milling is done with diamond disks or burs which cut the restorations from ingots.

0 kommentar(er)

0 kommentar(er)